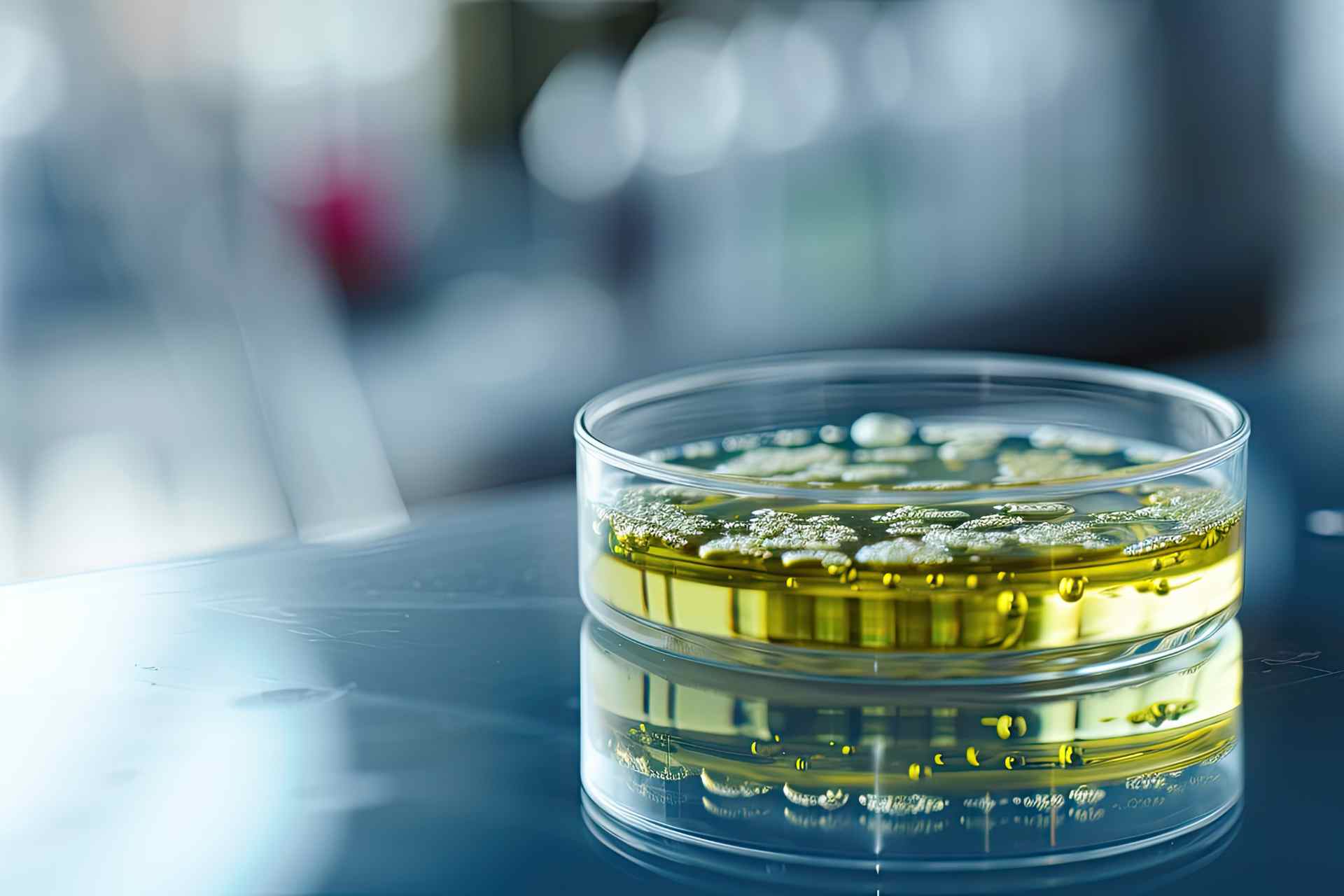

Bacteria are pivotal in producing live-biotherapeutics, probiotics, and food cultures, necessitating precise optimization of bacterial yield during fermentation and downstream processing. However, determining the perfect harvest window for bacteria presents a significant challenge. Traditional methods, such as measuring colony-forming units (CFUs), are time-consuming, often taking at least a day for colonies to appear on agar plates. This delay can lead to either premature harvesting, resulting in suboptimal yields, or late harvesting, causing underutilized production capacity and a higher proportion of dead cells in the final product.

Traditional challenges and the advent of Bactobox

Operators have typically relied on various indicators like optical density (OD), dissolved oxygen, and base addition to estimate the optimal harvest time. However, these methods frequently fall short in providing accurate timing, leading to inefficiencies in the production process.

Enter BactoBox by SBT Instruments—a revolutionary solution that promises to transform the way bacterial harvest timing is determined. BactoBox offers real-time measurements of intact cell concentrations, providing a clear and accurate indication of when to harvest.

Demonstrating BactoBox efficiency: the E. coli experiment

A simple batch experiment with E. coli in an atSpiro shake flask bioreactor highlights BactoBox’s capabilities. Off-line samples were analyzed using BactoBox, OD600, and plate counts. BactoBox measurements showed a strong correlation with the plate count CFU/mL values, indicating its reliability.

Optimal harvest timing: BactoBox data revealed that the optimal harvest time was approximately 6.8 hours, at which point the yield plateaued. Relying on the base addition trendline would have resulted in a premature harvest at 5.7 hours, while OD600 trendline would have delayed the harvest beyond 12 hours. Dissolved oxygen profiles failed to provide clear harvest timing insights, as oxygen consumption continues throughout the stationary phase.

Cell size indicator: BactoBox also measures object amplitudes, reflecting cell size. During early exponential growth, higher amplitudes indicate active cell division. As the culture reaches the stationary phase, amplitudes stabilize, signaling reduced cell activity and division.

Establishing new harvest criteria with BactoBox

To optimize bacterial harvest using BactoBox, follow these guidelines:

At-line BactoBox measurements: regularly analyze fermentation samples using BactoBox to reach a defined minimum target concentration of intact cells.

Hourly sampling near target: as the minimal target is approached, conduct hourly samples. A less than 10% increase in intact cell concentration from the previous sample indicates diminishing returns and signals harvest time.

Amplitude distribution observations: monitor amplitude distribution changes. When cell size stabilizes at a low level, it suggests that the bacteria are nearing the stationary phase, indicating the optimal harvest time.

Conclusion

BactoBox represents a significant advancement in optimizing bacterial harvest timing, ensuring higher yields and improved production efficiency. This innovative tool promises to eliminate guesswork, streamline fermentation processes, and maximize the yield of viable bacteria, thus revolutionizing the biotechnology and bioprocessing industries.